Excitement About Dust Extractors For Small Workshops

Dust Extractors For Small Workshops Things To Know Before You Buy

Table of ContentsNot known Details About Dust Extractors For Small Workshops 8 Easy Facts About Dust Extractors For Small Workshops ExplainedGetting The Dust Extractors For Small Workshops To WorkIndicators on Dust Extractors For Small Workshops You Should Know

The obstacles for shop dust collection systems focus on crystalline silica dust, carbon monoxide, and heat, which are toxic combinations. These elements make meeting air quality requirements tough as well as requiring. Therefore, when choosing a dirt control system for a factory, the very first consideration is the capacity of the system to hold up against rough and also harmful workplace conditions.

Dirt collection systems for this kind of operation must be especially developed to fit the kind of covering being used. The function of the system is to regulate as well as lessen overspray as well as dirt.

It would appear most likely to boost air movement and motion, this type of remedy might be inefficient and also waste energy. The layout of the cubicle depends on the pressure of the air getting in the cell or cubicle. For many systems, it is very important to have a slight vacuum cleaner in the booth to prevent possible positive pressure.

Dust Extractors For Small Workshops for Dummies

One more method is just putting the makeup air connection on the top of the cubicle. Despite the style, it is vital for the cleansing of the air to have cross air flow. Just like a cleanroom, air movement in a thermal spray booth can be either horizontal or downward, though the descending design is best for dust collection systems.

The pharmaceutical sector is a highly controlled sector with comprehensive as well as exact policies. Dirt from pharmaceuticals is produced mainly during the manufacturing and packaging of items. Each step of generating a drug, which consists of granulating, drying, mixing, pressing, covering, as well as grinding, generates huge amounts of dirt that need to be eliminated.

Obstructing and controlling this dissemination is the feature of the dust control system. When designing a dirt control system for a pharmaceutical plant, the first factor to consider is mapping the air flow system to track the course of dirt, fumes, existing air flow patterns, and also possible transformative changes. Since numerous pharmaceutical dirts are flammable, the style of the air flow system is incredibly vital.

HEPA filters are generally located in pharmaceutical dust control systems since they are the most effective and description trustworthy. Similar to a foundry system, they are installed as a secondary security to attain zero emissions. Reusing creates a lot of dirt as an all-natural outcome of decreasing products to their basic materials.

Rumored Buzz on Dust Extractors For Small Workshops

Dust stems after materials are shredded, squashed, or have paint or lacquer removed. All reusing centers are called for to follow air high quality criteria. As they function to fulfill quality standards as well as control pollutants, they have actually identified that dust control is a major issue, bring about the vast use dust collection systems to mitigate and consist of the problem. dust extractors for small workshops.

When manufacturers select a dirt control system, they are encouraged by manufacturers concerning the kind of system that would best fit More hints their needs given that buying and also setting up a dust control system is a significant financial investment. Particulate matter is available in a broad variety of types, from silicon dirt to wood chips as well as sawdust.

How Dust Extractors For Small Workshops can Save You Time, Stress, and Money.

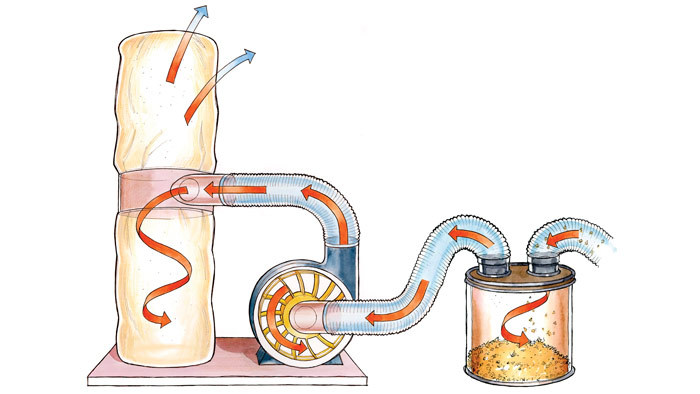

Textile filter bags in a cartridge system are the most efficient technique for collecting dirt. Dirt collection systems are covered to have the dirt as well as clean the air.

Plastic Dust High-Density Polyethylene (HDPE) dirt is produced in the production of plastic panels when they are shaped as well as developed on an edge trimmer, grinder, or miter saw. Paper YOURURL.com Dirt One of the a lot more typical types of dirt is paper dust, the negative effects of the production of various sorts of paper.

With the intro of dust collection systems, workers are safer and also extra secured. Sugar Sugar dust is the byproduct of the manufacturing of sweet. Pulse jet systems are used to keep the filters of the dust collection system particulate-free. The accumulated product is gotten rid of as well as collected in drums. Zinc Zinc dirt is created in the galvanizing process.

Rice Dust Rice dirt has extremely fine as well as minute fragments that accumulate during the production of rice-based products. A dirt collection system is required for the security as well as security of workers.